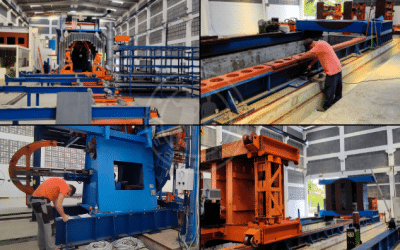

“I Need to be 100% Efficient in my GRP Manufacturing Plant!”

This is the answer that I have received from our customer when I asked him WHY HE BUYS the aluminum beams for the Continuous Winder FROM TOPFIBRA.

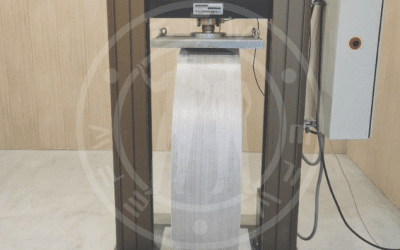

Our customer knows that TOPFIBRA’s aluminum beam includes the sliders for the pusher. In my opinion, it is always better to buy aluminum beam with sliders, so that you always replace the old ones without the need to change the sliders.

The aluminum beam’s sliders are made of a special material (not simply brass), so the component has a longer lifespan.

The slider assembly is done with high-performance coils to avoid “surprises” during the GRP production.

The aluminum beam bearings are of the “slow rotation – high pressure” type. The resistance of such bearings on slow rotation gives a lifetime improvement higher than 32%.

Are you still working with classic spare parts? This means that you are giving a big advantage to your competitor.