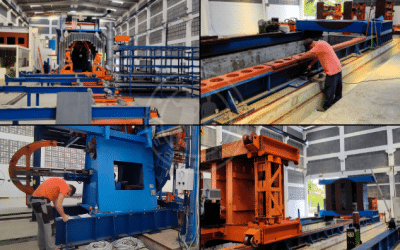

We have completed the 36-hour course in a CFW Plant regarding the EFFECTIVE FILAMENT WINDING® method.

First results?

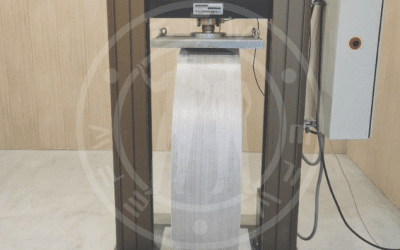

- Savings on Pipe cost: 8%;

- Quality control results: 100% approved;

- Reduction of the scrap: 3%;

- A clear strategy of the process and full control of the results.

Book a free 30 min call with us by clicking on the link below, to discuss the roadmap to how your plant could immediately benefit from our EFW® method!